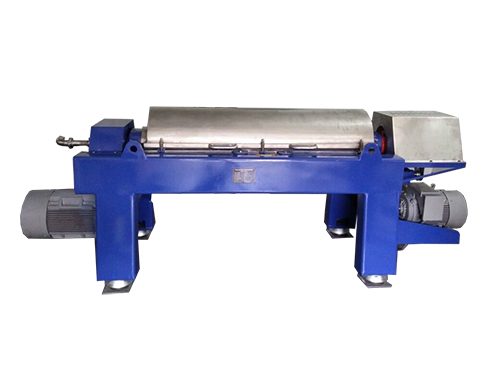

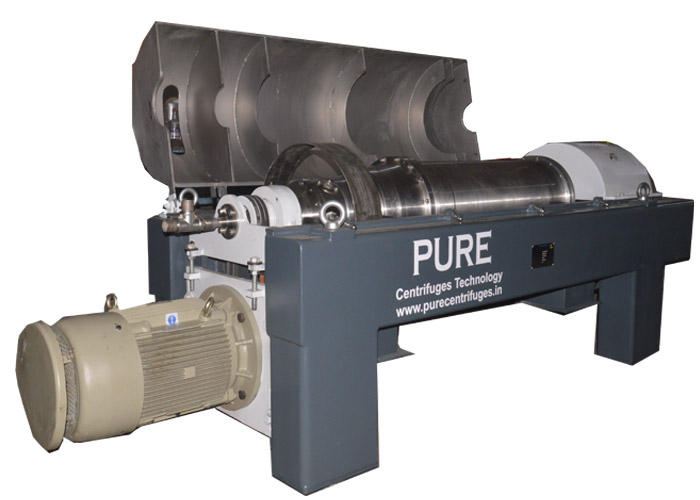

We are Manufacturer, Supplier, Exporter, Wholesaler, Trader of Decanter Centrifuges (Decanter Centrifuge Machines), Solid Bowl Decanter Centrifuges, Horizontal Decanter Centrifuges, Industrial Decanter Centrifuges, High Quality Decanter Centrifuge Machines, Super Decanter Centrifuges, Continuous Type Decanter Centrifuges, 2 (Two) Phase Decanter Centrifuges, Decanter Centrifuge Mobile Units, Skid Mounted Decanter Centrifuges from Pune, Maharashtra, India. We also provide Reconditioned / Refurbished Decanter Centrifuges, Spares (Spare Parts) for the whole range of any brand’s Decanter Centrifuges. We also provide AMC (Annual Maintenance Contract) Services, Repairing Services. Our range is applicable for Fish Meal And Oil Industries, Petrochemical Industries, Crude oil Filtration, Muddy Juice Filtration In Sugar Industries, Oats Milk Filtration, Animal Feed Industries, Mango Pulp Industries, Paper Mill, Drilling Mud Filtration, ETP (Effluent Treatment Plants), STP (Sewage Treatment Plants), Chemical Industries, Food Industries, Bio Industries, Pharmaceutical Industries.

We provide our whole range to ALL OVER THE WORLD, but we majorly target customers from Gulf countries like Bahrain, Iraq, Kuwait, Oman, Qatar, Saudi Arabia, UAE ( United Arab Emirates ), Doha, Iran, Turkey, Yemen, Lebanon, Egypt, Algeria, Ghana, Ethiopia, Nigeria, Congo, Uganda, Kenya, Sudan, Tanzania, Zambia, Angola, Zimbabwe, Namibia, Mozambique, South Africa, Mauritius, China, Malasia, Philipines, Singapore, Thailand, Sri Lanka, Bangladesh, Russia.

A decanter centrifuge is a sedimentation centrifuge for separation of suspended solids from one or two liquids. The characteristic which distinguishes a decanter centrifuge from other types of centrifuges such as disc stack

Description / Advantages

A decanter centrifuge; consists of a solid cylindrical bowl rotating at high speed, a scroll rotating at the same axis with a slightly different speed, a drive group adjusting the speed difference and the body which carries all the rotating elements.

- Application flexibility

- Easy installation

- Corrosion and wear protection

- Personnel safety

- Operational conditions

- Automation

- Low space requirement

Applications

- Municipal waste water treatment plants

- Industrial waste water treatment plant

- Paper production mills treatment plants

- Corrosion and wear protection

- Personnel safety

- Dewatering

- Fish meal and fish oil extraction

- Foods & Beverages Plants

Specification

| DECANTER CENTRIFUGE SPECIFICATION | ||||||

| SR. NO. | MODEL | PC 210 | PC355L /1/2/3 | PCSWG 355L /1/2/3 | PC 455L /1/2 | PCSWG455L /1/2 |

| (MANU/AUTO) | (MANU/AUTO) | (MANU) | (MANU/AUTO) | (MANU/AUTO) | ||

| CAPACITY (MAX.) | 4 KL / HR | 5 / 10 / 15 KL / HR. | 5 / 10 / 15 KL / HR. | 30 / 50 KL/HR. | 30 / 50 KL/HR. | |

| Above Max capacity is for water, the treating capacity would be various as per different material conditions and customer required treating results. | ||||||

| 2 | BOWL | |||||

| A | MOC | SS 304 / 316 / 316L | SS 304 / 316 / 316L | SS 304 / 316 / 316L | SS 304 / 316 / 316L | SS 304 / 316 / 316L |

| B | BOWL DIAMETER | 210 MM | 355 MM | 355 MM | 455 MM | 455 MM |

| C | CYLINDER LENGTH | 500 MM | 300 / 600 / 900 MM | 300 / 600 / 900 MM | 850 / 1700 MM | 850 / 1700 MM |

| D | CONE ANGLE | 8.5 DEGREE | 8.5 DEGREE | 8.5 DEGREE | 8.5 DEGREE | 8.5 DEGREE |

| E. | MAX. BOWL RPM | 5000 | 4000 | 4000 | 3250 | 3250 |

| F. | MAX. G FORCE | 2934 | 3175 | 3175 | 2680 | 2680 |

| 3 | CONVEYOR | |||||

| A | MOC | SS 304 / 316 / 316L | SS 304 / 316 / 316L | SS 304 / 316 / 316L | SS 304 / 316 / 316L | SS 304 / 316 / 316L |

| B | CONVEYOR PITCH | 75 / 90 MM | 75 / 110 / 140 MM | 75 / 110 / 140 MM | 140 / 180 MM | 140 / 180 MM |

| C | WEAR PROTECTION | |||||

| 4 | GEAR BOX | PLANETORY TYPE | PLANETORY TYPE | PLANETORY TYPE | PLANETORY TYPE | PLANETORY TYPE |

| A | TORQUE | 0.4 KNM | 2.5 / 3.0 / 3.5 KNM | 2.5 / 3.0 / 3.5 KNM | 2.5 / 3.0 / 3.5 KNM | 2.5 / 3.0 / 3.5 KNM |

| B | GEAR RATIO | 1:47 | 1:159.5 / 1:97 / 1.57 | 1:159.5 / 1:97 / 1.57 | 1:159.5 / 1:97 / 1.57 | 1:159.5 / 1:97 / 1.58 |

| C | BACK DRIVE TYPE | SAFETY CLUTCH/AC MOTOR | SAFETY CLUTCH/AC MOTOR | SAFETY CLUTCH | SAFETY CLUTCH/AC MOTOR | SAFETY CLUTCH/AC MOTOR |

| 5 | MAIN DRIVE | 7.5 HP / 3000 RPM / 50HZ | 25/ 30/ 40 HP / 1440 RPM | 25/ 30/ 40 HP / 1440 RPM | 40/ 50/ 60 HP / 1440 RPM | 40/ 50/ 1440 RPM |

| 6 | BACK DRIVE | 3.0 HP / 3000 RPM / 50HZ | 7.5/ 10 / 15 HP / 3000 RPM | 7.5/ 10 / 15 HP / 3000 RPM | 10/ 15/ 20 HP / 3000 RPM | 10/ 15/ 20 HP / 3000 RPM |

| NOTE :- | PCSWG SERIES HAS BEEN DESIGNED FOR SEWAGE TREATMENT ONLY, WITH LEAST PRICE. | |||||