We are Manufacturer, Supplier, Exporter, Wholesaler, Trader of Tricanter Centrifuges (Tricanter Centrifuge Machines), Solid Bowl Tricanter Centrifuges, Horizontal Tricanter Centrifuges, Industrial Tricanter Centrifuges, High Quality Tricanter Centrifuge Machines, Super Tricanter Centrifuges, Continuous Type Tricanter Centrifuges, 3 (Three) Phase Tricanter Centrifuges, Tricanter Centrifuge Mobile Units, Skid Mounted Tricanter Centrifuges, Tricanter Centrifuges For 3 (Three) Phase Separation from Pune, Maharashtra, India. We also provide AMC (Annual Maintenance Contract) Services, Repairing Services. Our range is applicable for Fish Meal And Oil Industries, Petrochemical Industries, Crude Oil Filtration, Animal Feed Industries, Chemical Industries, Olive Oil Industries.

We provide our whole range to ALL OVER THE WORLD, but we majorly target customers from Gulf countries like Bahrain, Iraq, Kuwait, Oman, Qatar, Saudi Arabia, UAE ( United Arab Emirates ), Doha, Iran, Turkey, Yemen, Lebanon, Egypt, Algeria, Ghana, Ethiopia, Nigeria, Congo, Uganda, Kenya, Sudan, Tanzania, Zambia, Angola, Zimbabwe, Namibia, Mozambique, South Africa, Mauritius, China, Malasia, Philipines, Singapore, Thailand, Sri Lanka, Bangladesh, Russia.

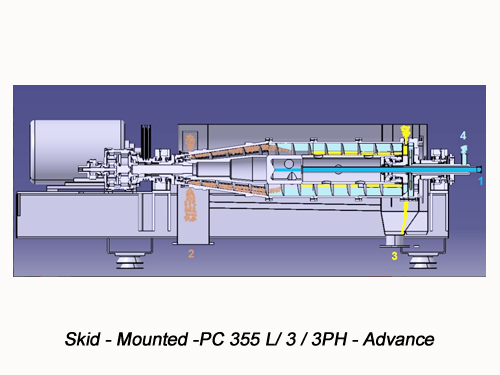

In the figure you can see the different channels of all the liquid and solid phases. To optimize the separation results, there is a valve provided at heavy liquid phase outlet. By closing or opening the valve you can increase or decrease the pressure on the light liquid phase which doesn't allow the oil to go inside the stick water and prevents the losses and gives you clear light liquid phase even after changing the consistency of both liquids. Please find the photographs in the next slide.

A decanter centrifuge is a sedimentation centrifuge for separation of suspended solids from one or two liquids. The characteristic which distinguishes a decanter centrifuge from other types of centrifuges such as disc stack

Tricanter Centrifuges (Tricanter Centrifuge Machines)

A decanter can not only separate solids from liquid, but it can also separate two immiscible liquids. A three phase decanter can discharge two liquid phases and one solid phase.

The light liquid phase is discharged in to the casing through radial pockets made on the partition hub and the heavy liquid phase discharged through axial outlet tube connected with centripetal pump fitted inside the main hub.

The liquid radius for the light phase is smaller than the radius for the heavy liquid phase. To avoid the intersection of two separated liquids the separating disc is fitted inside the partition hub. The uniqueness of the Tri-canter designed by ‘PURE CENTRIFUGES’ is centripetal impeller fitted inside the main hub. It can control the separation quality even incase of change in consistency of the two liquids. It is useful to get the desired results without changing plate dams even after change in the oil & water percentage. It optimizes the separation quality at maximum level. See the figure in next slide.