We are Manufacturer, Supplier, Exporter, Wholesaler, Trader of Tubular Centrifuges (Tubular Centrifuge Machines), High Speed Tubular Centrifuges, Super Centrifuges, Separator Type Tubular Centrifuges, High Quality Centrifuge Machines, Clarifier Type Tubular Centrifuges from Pune, Maharashtra, India. We also provide Spares (Spare Parts) for the whole range of any brand. We also provide AMC (Annual Maintenance Contract) Services, Repairing Services. Our range is applicable for Chemical Industries, Edible Oil Industries, Bio Industries, Pharmaceutical Industries, Vaccine Manufacturing Industries, Fermented Broth Filtration, Fish Oil Filtration.

We provide our whole range to ALL OVER THE WORLD, but we majorly target customers from Gulf countries like Bahrain, Iraq, Kuwait, Oman, Qatar, Saudi Arabia, UAE ( United Arab Emirates ), Doha, Iran, Turkey, Yemen, Lebanon, Egypt, Algeria, Ghana, Ethiopia, Nigeria, Congo, Uganda, Kenya, Sudan, Tanzania, Zambia, Angola, Zimbabwe, Namibia, Mozambique, South Africa, Mauritius, China, Malasia, Philipines, Singapore, Thailand, Sri Lanka, Bangladesh, Russia.

The tubular super centrifuges are the machines fitted with vertical axis that are used for the recovery of solids or elimination of liquid suspended impurities, and for the separation of two non miscible liquids of different densities, using the centrifugal force by means of suspended high revolution rotors ( bowl ).

Description / Advantages

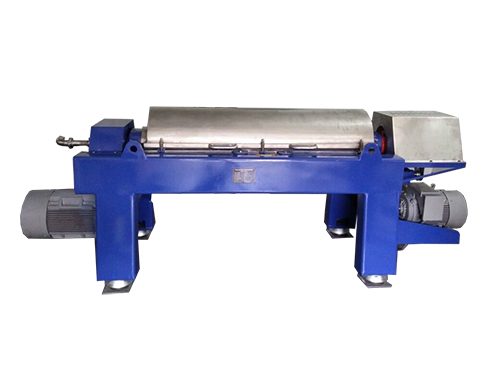

A decanter centrifuge; consists of a solid cylindrical bowl rotating at high speed, a scroll rotating at the same axis with a slightly different speed, a drive group adjusting the speed difference and the body which carries all the rotating elements.

- Simple strong structure

- Tensor system allowing to take the rotor out without dismantling the belt.

- Installation without foundation as forces are not transmitted on the floor.

- Simple access and easy cleaning.

- Revolving top head assembly for the easy extraction of the bowl in the bigger size.

- Cooling or heating system possibilities.

Applications

- Covers wide range of applications for both separating and clarifying liquid.

- Essential oils.

- Varnishes

- Paints

- Separation of human & animal plasma & red cells

- Separation of virus & bacteria’s

- Wax purification

- Separation & clarification of lube oils, greases, & solvents

- Biotechnological solutions

| Type of machine | Flow Capacity in l/h | Max. Velocity in PRM | G force Max. | Dm3 | Diameter in mm | Power in Kw | Net weight in Kg. | Machine size |

| PC 5 C/S | 500 / 1200 | 16000 | 15000 × G | 5 | 105 | 2.2 | 350 | 1.8 × 0.8 × 1 m. |

| PC 8 C/S | 800 / 2000 | 14650 | 15000 × G | 8 | 126 | 3.7 | 500 | 1.8 × 1.3 × 0.8 m. |